Fiber optic cables serve as the backbone of modern telecommunications networks, transmitting vast amounts of data across long distances with minimal signal loss. Ensuring the quality and reliability of these cables is paramount to maintaining seamless connectivity. Thorough testing procedures are therefore essential to verify the performance and durability of fiber optic cable products before deployment. This article outlines the key steps involved in testing fiber optic cables.

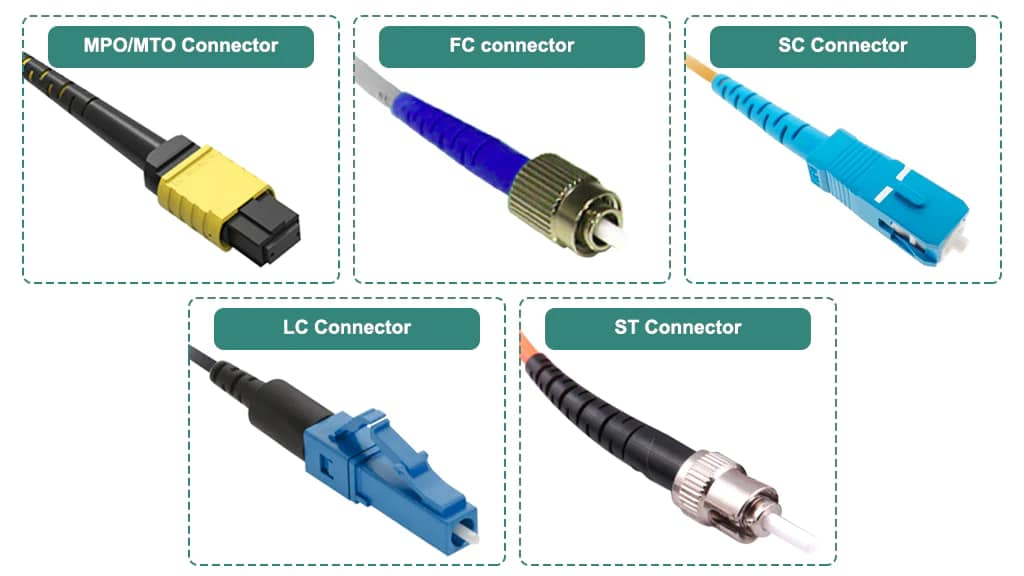

1. Visual Inspection: The testing process begins with a visual inspection of the cable's exterior, connectors, and terminations. Any physical defects such as scratches, cracks, or contamination are noted and addressed to prevent potential signal degradation or failure.

2. Optical Loss Testing: Optical loss, or attenuation, is a critical parameter that measures the reduction of signal strength as it travels through the fiber optic cable. This test involves sending a known light signal through the cable and measuring the loss at various points using specialized equipment such as an optical time-domain reflectometer (OTDR) or optical power meter.

3. Insertion Loss and Return Loss Testing: Insertion loss refers to the amount of signal loss that occurs when a connector is inserted into the cable, while return loss measures the amount of light reflected back towards the source. These tests ensure that connectors are properly aligned and that signal reflections are minimized to maintain signal integrity.

4. Mechanical Testing: Fiber optic cables are subject to various mechanical stresses during installation and operation, including bending, twisting, and tensile forces. Mechanical testing assesses the cable's ability to withstand these stresses without compromising performance or reliability. This may involve bend radius testing, tensile strength testing, and vibration testing.

5. Environmental Testing: Fiber optic cables may be exposed to harsh environmental conditions such as temperature extremes, moisture, and chemical exposure. Environmental testing evaluates the cable's resistance to these factors to ensure long-term durability and reliability in real-world applications.

6. Durability Testing: Durability testing simulates the repeated mating and unmating of connectors to assess their longevity and reliability over time. This ensures that connectors maintain proper alignment and optical performance even after multiple cycles of connection and disconnection.

7. Compliance Testing: Finally, fiber optic cable products must undergo compliance testing to ensure they meet industry standards and specifications, such as those set by organizations like the International Electrotechnical Commission (IEC) or the Telecommunications Industry Association (TIA).

In conclusion, thorough testing of fiber optic cable products is essential to ensure their quality, reliability, and performance in telecommunications networks. By adhering to rigorous testing procedures throughout the manufacturing process, manufacturers can deliver products that meet the demanding requirements of modern communication systems.

Welcome to caontact our website:www.yitofc.com

Email:allen@yitofc.com

Contact: Allen

Phone: +86 18025260951

E-mail: allen@yitofc.com

Whatsapp:+86 18025260951

Add: No.166 Old Road Nanhuang Zhongtang Town Dongguan City Guangdong Province

We chat