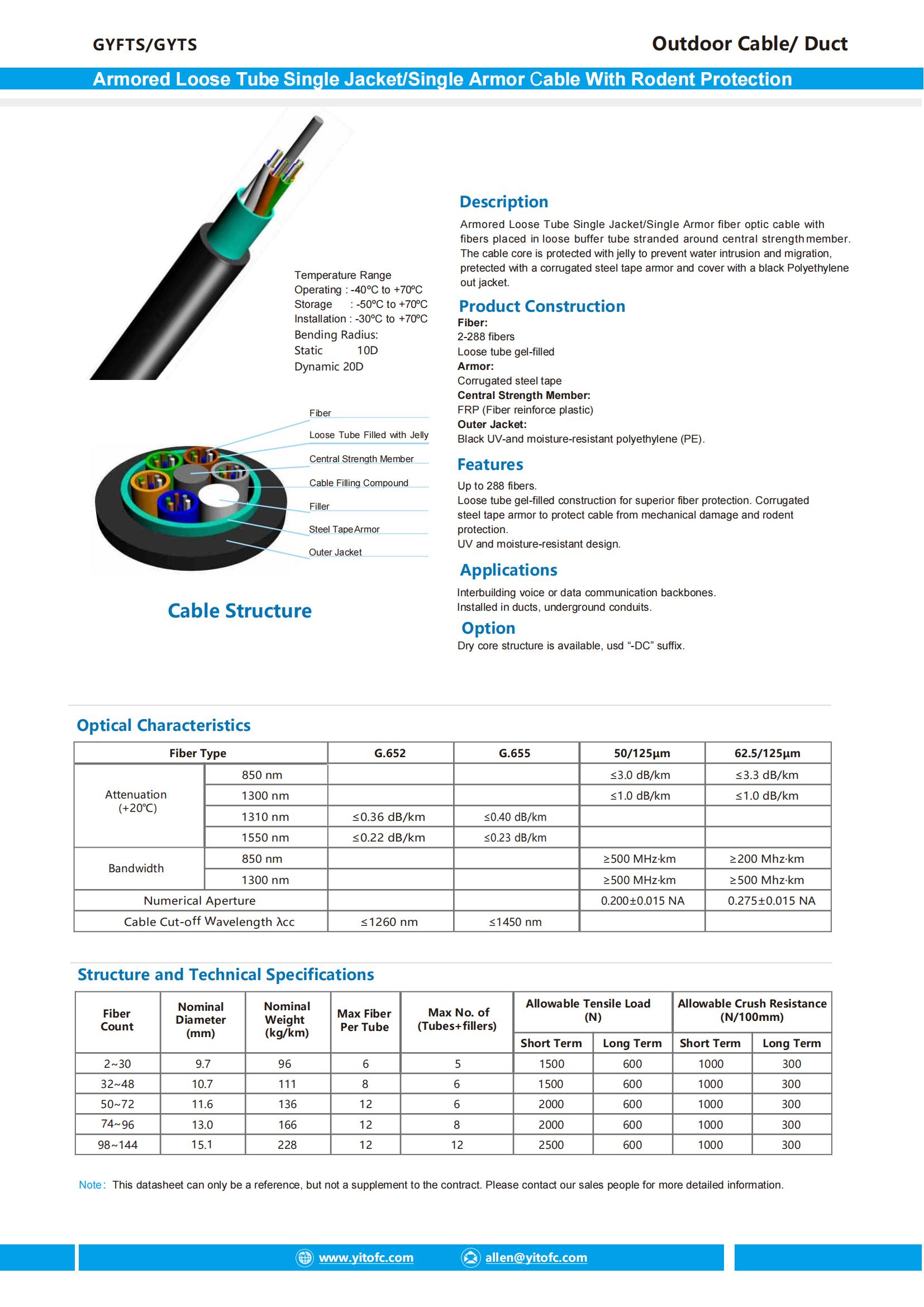

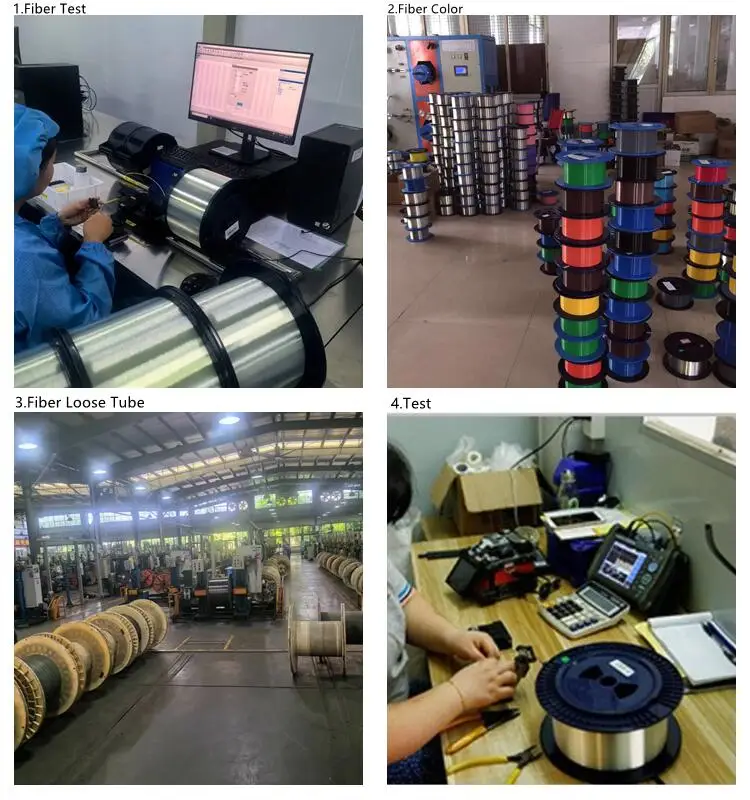

The fibers, 250μm, are positioned in a loose tube made of a high modulus plastic. The tubes are filled with a water-resistant filling compound. Over the tube. water-blocking material is applied to keep the cable watertight. Two parallel Fiber Reinforced Plastics (FRP) are placed at the two side. The cable is completed with a polyethylene(PE) sheath.

![]()

![]()

![]()

![]()

![]()

![]()

![]()

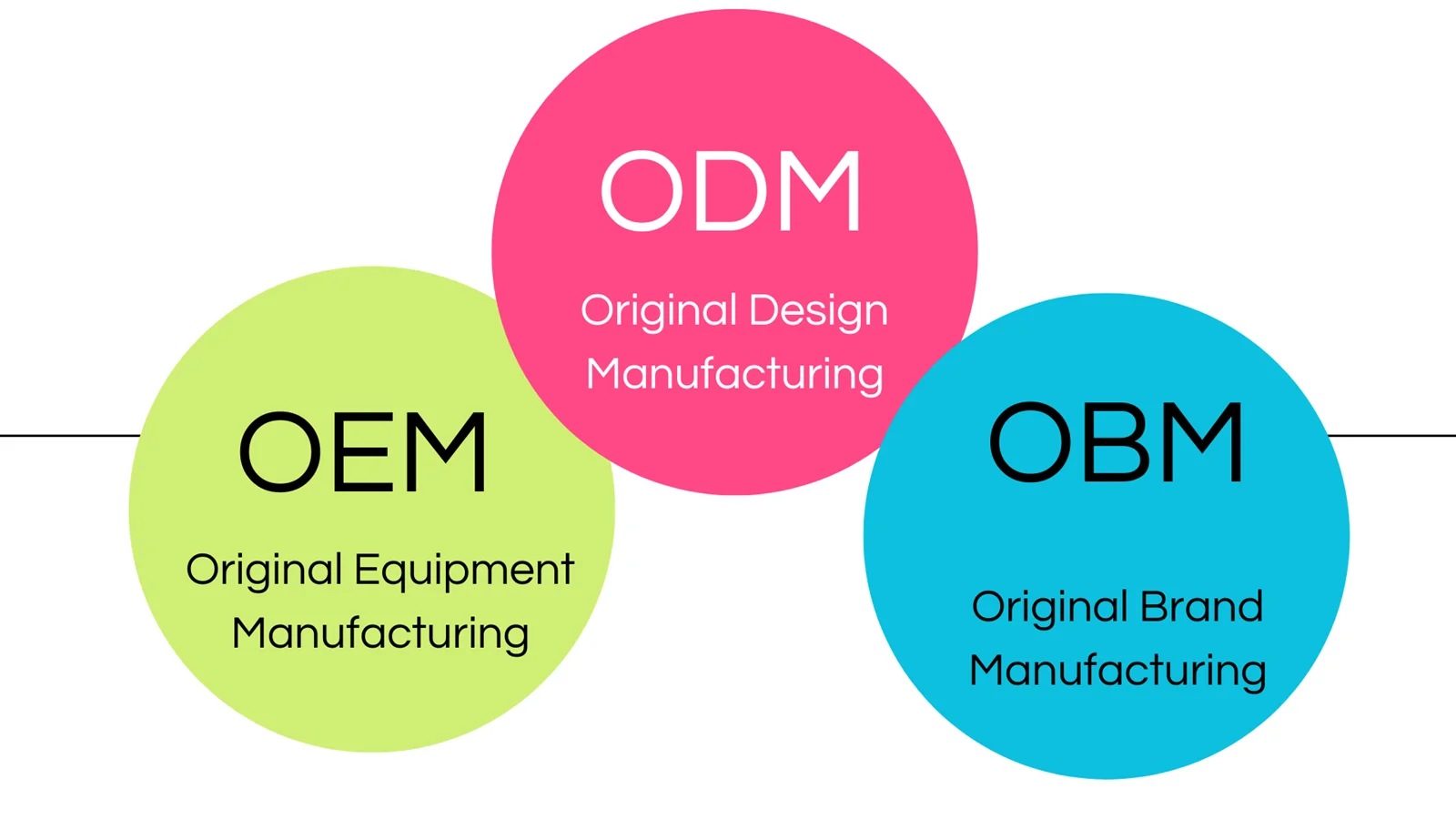

Q: Are you trading company or manufacturer ?

A: We are a OEM & ODM China manufacturer since 2015

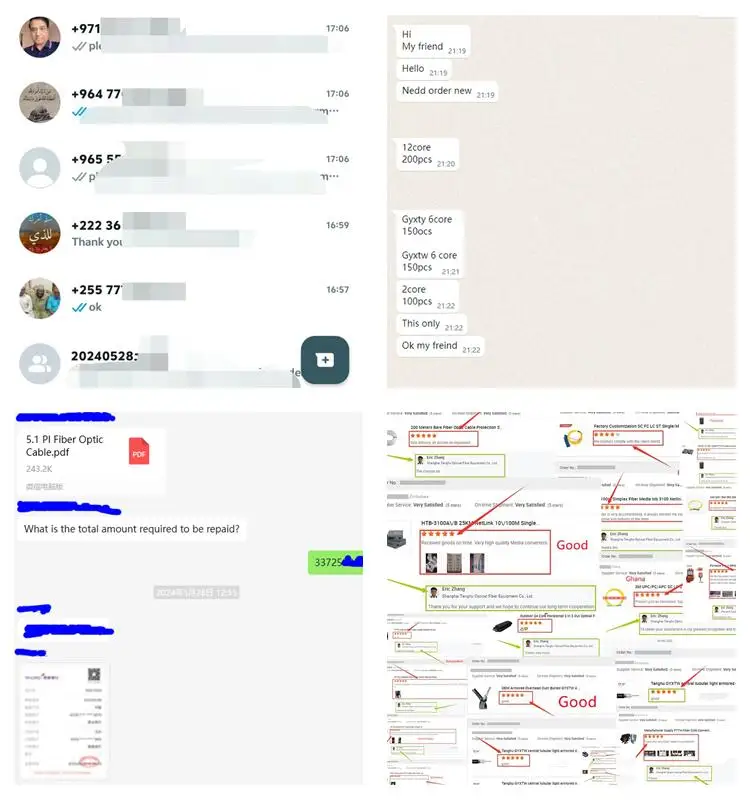

Q: What is the MOQ

A: MOQ depends on our clients demands, we welcome trial order before mass production.

Q: How does your factory make sure the product quality?

A: First, we will prepare samples for approval, Second, after getting approvalled, our team will set up a process craft , and form a inside drawing to follow it.Third, durning production, we have IQC , IPQC and OQC to control the quality.Forth, We will final check before shipping to avoid any problem.

Q: What is your terms of payment ?

A: T/T, Ali-pay,West Union, Cash, Paypal, 30% T/T in advance ,balance before shippment etc.

Q:Wonder if you accept small orders?

A:Do not worry. Feel free to contact us .in order to get more orders and give our clients more convener ,we accept small order.

Q:Can you send products to my country?

A:Sure,we can.If you do not have your own ship forwarder, we can help you.

Q:Can you do OEM for me?

A: We accept all OEM orders,just contact us and give me your design.we will offer you a reasonable price and make samples for you ASAP.

Q: How can I place the order?

A: First sign the PI,pay deposit,then we will arrange the production.After finished production need you pay balance. Finally we will ship the Goods.

Q: When can I get the quotation ?

A: We usually quote you within 24 hours after we get your inquiry. If you are very urgent to get the quotation.Please call us or tell us in your mail, so that we could regard your inquiry priority.

Q: What is delivery time if we place an order?

A: It depends order quantities. Usually, We can deliver goods within 3-5 working days for small orders, for more QTY. order, Let's confirm when you place offical order

Contact: Allen

Phone: +86 18025260951

E-mail: allen@yitofc.com

Whatsapp:+86 18025260951

Add: No.166 Old Road Nanhuang Zhongtang Town Dongguan City Guangdong Province

We chat